Nikko leading the support for restaurant sustainability

Nikko Corporation is a long-established fine porcelain manufacturer founded in 1908 and based in Ishikawa Prefecture, and is serious in a transition towards a circular economy model for its tableware. Renowned for providing high-quality dinnerware, including bone china, Nikko is widely recognized in the hotel and restaurant industry. In April 2021, Nikko launched the “NIKKO Circular Lab,” a project aimed at promoting the circular economy in the ceramic industry.

With over a century of history, Nikko was initially established as “Nippon Hard Porcelain Co., Ltd.” in Kanazawa, Ishikawa Prefecture. Its primary objective was to manufacture high-quality tableware to generate foreign currency. In 1978, they developed “Nikko Fine Bone China,” increasing the bone ash content to 50% and earning a reputation for producing the world’s whitest china. Over the years, Nikko diversified its business, with the ceramic tableware division becoming one of its core pillars alongside the housing equipment and functional ceramic product divisions.

The ceramic industry, including Nikko, has been facing significant challenges. According to the Ministry of Economy, Trade and Industry and the Japan Ceramic Manufacturers Association, the annual production value of “daily-use ceramics” has decreased by approximately 70%, from 78.1 billion yen in 2003 to 27.1 billion yen in 2018. This decline is attributed to the rise of low-cost imported products and prolonged economic downturn.

Nikko’s ceramic business also experienced declining sales since the 1980s, and as a company serving hotels and restaurants, they were directly impacted by the COVID-19 pandemic.

The era of “produce, use, and discard” characterizes the current linear model in the ceramic industry. However, the depletion of high-quality clay and stone resources, essential for ceramic production, has become evident globally. Even in regions with remaining raw material reserves, further extraction becomes challenging once buildings are constructed. Ceramic manufacturers worldwide are actively searching for high-quality raw materials, resulting in price hikes. Nikko, known for its pure white porcelain, also needs to address this issue.

There are numerous environmental challenges from the end-users’ perspective as well. In the commercial sector, tableware often functions as consumables. Mr. Mitani acknowledges this situation, stating, “In the market, there is a growing perception that even inexpensive imported tableware that easily breaks is acceptable. However, our resources are depleting. It is necessary to convey this reality.”

“Nikko Circular Lab” – Key to Transitioning to a Circular Model

To leverage their durable and break-resistant products and transition their ceramic business towards a circular model, Nikko established the cross-functional project, “Nikko Circular Lab.”

The lab’s theme is “Designing a Circular Future for 100 Years Ahead.” Its mission is to create business strategies for the next century of Nikko, a company with over a century of history. The lab actively engages in various projects throughout the entire product lifecycle to achieve circular ceramic production aligned with the principles of the circular economy. Notably, they openly share the technical challenges they face. Let’s explore a few selected projects within the product lifecycle.

Circular Design: Designing for Long-Term Use

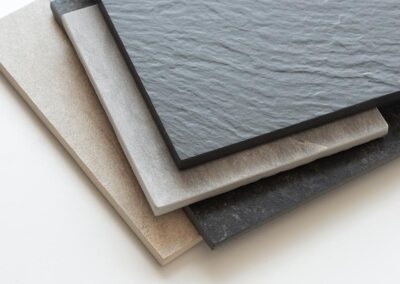

Improving durability is a primary consideration for extending the product lifespan. During the design phase, Nikko focuses on leveraging their existing strength in durability and creating timeless designs that withstand changing trends.

From a durability standpoint, patterns painted with gold or platinum often peel off. To address this, Nikko developed a decoration method called “GP guard,” which increases wear resistance by 400% compared to conventional products. They also enhance dishwasher durability by five times.

From a design perspective, tableware plays a significant role in enhancing the dining experience. However, there is a tendency to replace tableware based on seasons or trends, resulting in the disposal of still usable products. In response, Nikko embarked on developing “lifelong usable products” with colors and shapes that transcend trends. The upcoming “Remastered” series, set to be released in mid-May, carefully selects designs from thousands of past creations. By pursuing “timeless designs,” Nikko aims to achieve emotional durability in addition to functional durability.

The design stage plays a vital role in transitioning to circular products. Nikko recognizes its importance as it significantly influences subsequent processes. In addition to durability and design, they also prioritize circular design initiatives, such as the recycling of raw materials after firing and research and development of alternative resources.

Building a Sustainable Company for the Next 100 Years

When asked about their future endeavors, Mr. Mitani stated, “There are plenty of things we want to tackle. For example, collaborating with member restaurants of the Japan Sustainable Restaurant Association (SRA) to develop new products. It would be an honor to work with individuals who resonate with our efforts.”

Nikko’s challenge has just begun. With a sense of pride in creating high-quality products, they have a strong desire to preserve the company and its products in any form. To achieve this, they believe engaging in dialogue with restaurant owners, actively pursuing sustainability, and expanding their fan base are essential. Mr. Mitani envisions a future where they continue to make a positive impact.

For Nikko to survive beyond its centennial milestone and remain relevant for the next century, it is crucial to address sustainability across the industry. This involves the global environmental impact of food, as well as the efforts of producers, restaurants, hotels, suppliers, and all stakeholders involved. Joining the SRA is merely the first step, and the true journey is just beginning.

Excerpt from IDEAS FOR GOOD.